Objective

The mission of RadiFLAT is the realization of the worldwide first radar-based strip flatness and bandwidth control to optimize strip flatness and width in strip processing lines. The basic technology consists of a multi-radar system which is created to operate with a high frequency of up to 300 GHz and delivers reliable measurements even within an extremely hostile process environment (dust, vapour, high temperatures, vibrations, etc.). For this purpose the development of sophisticated signal processing with integrated disturbance compensation is essential.

Application

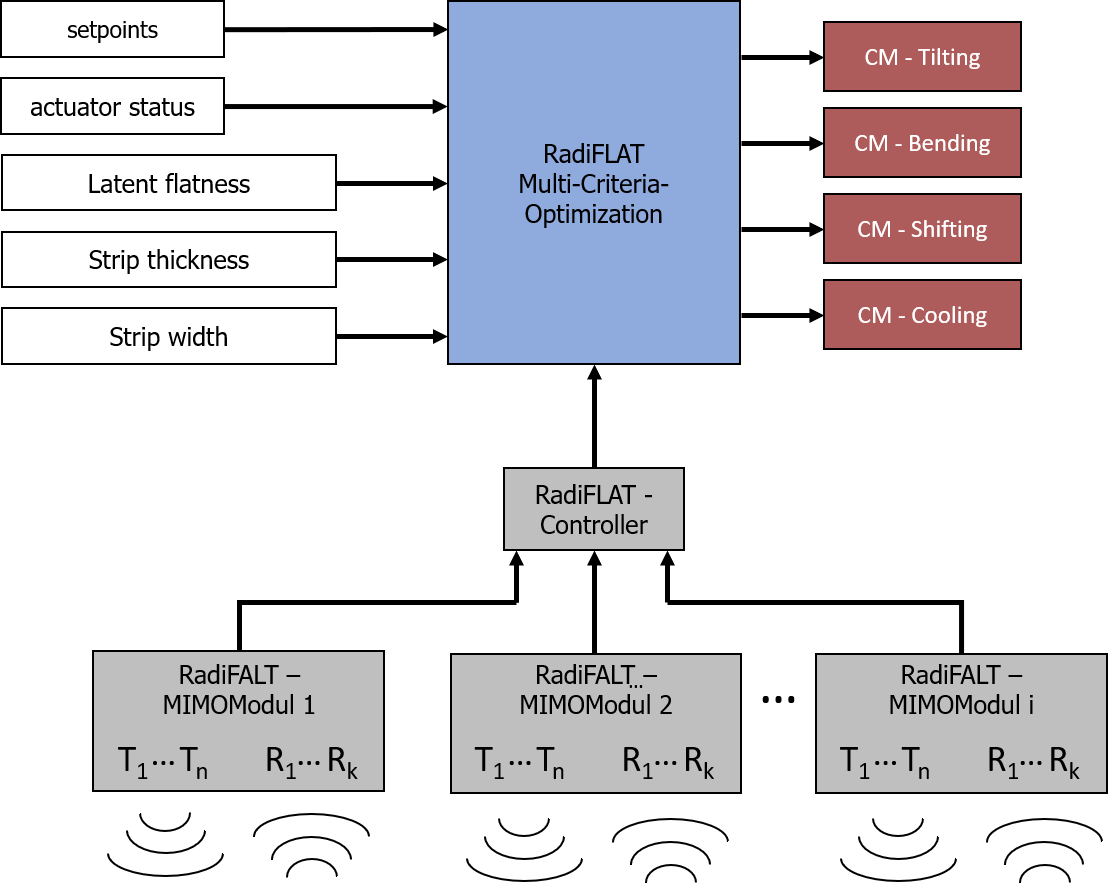

Based on a novel MIMO radar measuring system which is to be developed and tested, a possibility for control of strip flatness and bandwidth in strip processing lines is intended to be created within the RadiFLAT project.

The implemented control algorithms should be able to perform a multi-criteria optimization, which also considers process influenced criteria like strip thickness, energy consumption, material usage and productivity.

This is acquired by the usage of one or more arrays of radar sensors (N transmitters x N receivers), with their unique advantage of robust functionality in wet or dusty environments, where optical systems reach their limits. The short wavelengths at high frequencies allow highly integrated sensors, which, in combination with highly accurate phase measurement, advanced signal processing and disturbance compensation, ensure a precision in the micrometer range. Height distribution can then be converted to other representations like the length (I-Unit) distribution.

Additionally, two radar sensors are integrated to precisely detect the edge areas, to provide accurate flatness control.

Unique Selling Points

Currently used control methods for manifested strip flatness are mainly based either on optical/laser triangulation or, rarely, thermographic measurement systems.

- Due to their complexity and maintenance intensity, these systems are very costly.

- Above named sensor systems react very sensitively to the prevailing harsh environmental conditions in the steel processing industry.

- When utilizing conventional measuring systems for strip flatness, a certain minimum distance must be maintained in most cases, which has a negative impact on the retrofittability and integration capability of such systems into existing structures.

Compared to these kind of sensors the novel measuring system which is intended to be the basis of RadiFLAT strip flatness and bandwidth control, has remarkable benefits.

- As it is engineered as a cost-efficient, scalable system

and compact regarding electronic as well as mechatronic components, to ensure a wide and flexible applicability, even at measurement points with limited access.

and compact regarding electronic as well as mechatronic components, to ensure a wide and flexible applicability, even at measurement points with limited access. - Measuring accuracy in micrometer range with simultaneous robustness against harsh operating conditions due to independency of optical and acoustic effects and automatic compensation of occurring disturbances (vibrations, strip movement, etc.)

- To achieve real-time measurement recent developments in the field of processor and semiconductor technology are used and complemented by efficient signal processing.

Budget & Time

The RadiFLAT-Project will be finished with 31st December 2021 and has a total budget of 1.74 million €. It receives funding from the Research Fund for Coal and Steel (RFCS).